An essential part of the modernization and overhaul of used machines is the possibility of reworking precision gears or even manufacturing completely new ones.

Your contact person: André Haas

Division Precision Gear Manufacturing Worm Gears and Mechanical Manufacturing

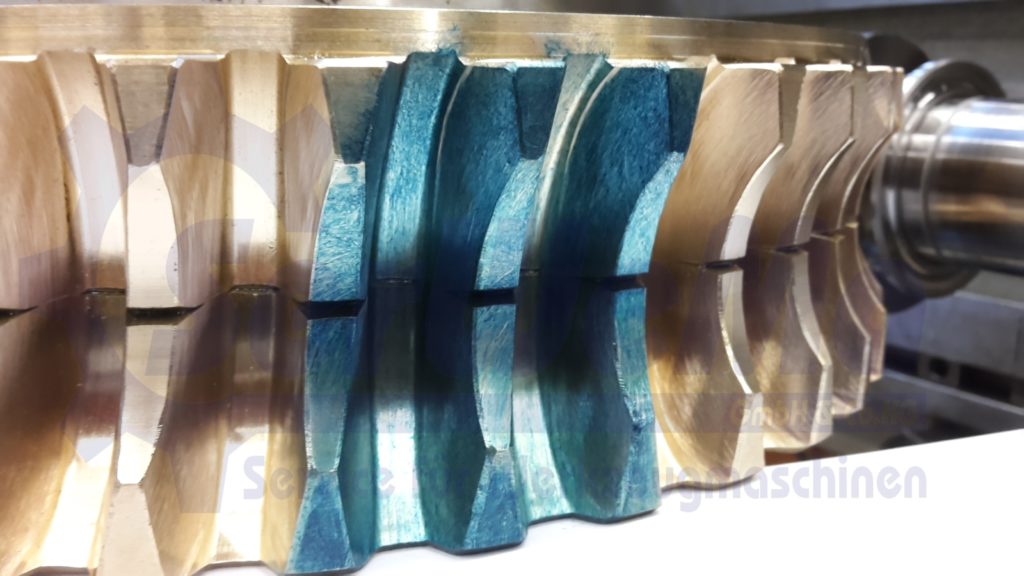

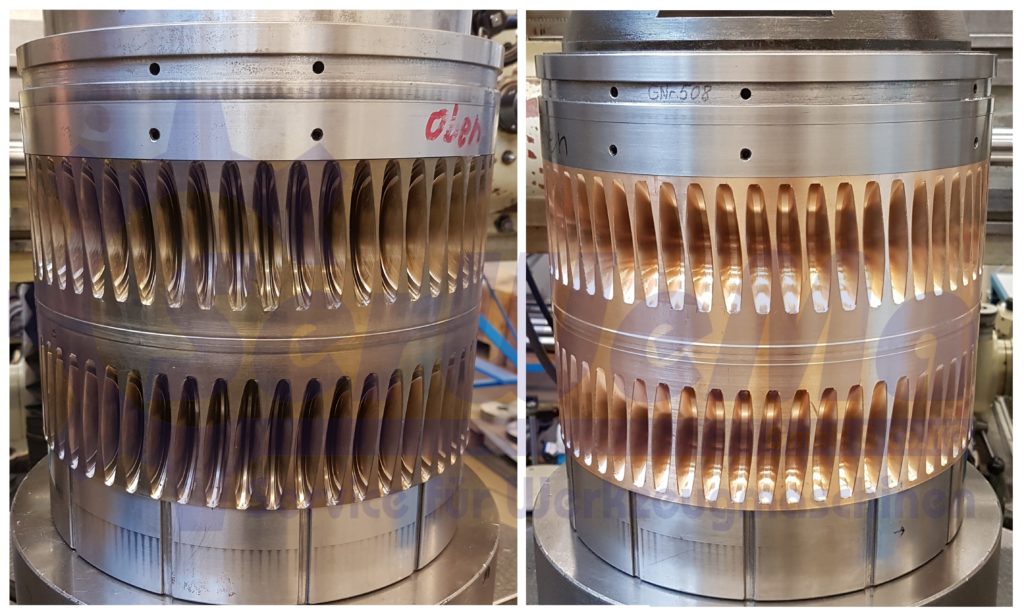

High-precision worm gears for positioning or indexing tasks, worm gears in standard quality

We are specialized in the production of high precision worm gears. The production, in a quality class 3 or better according to DIN 3974, requires an optimal interaction of many influencing factors. For example, machining is carried out on high-precision machines from PFAUTER, MODUL, Klingelnberg and Mikromat.

But in the end it is of secondary importance what type or accuracy of worm gears you need, we will be pleased to check your requirements!

We manufacture among other things:

- Cylindrical worm gears

- Duplex worm gear units

- Worm gear units with special gear teeth

- Various backlash adjustable special gears

- according to drawing or if necessary according to sample

- single pieces, small series and medium series

Machining diameter of worm wheel:

up to Ø2.300 mm

(larger diameters possible in cooperation)

Machining diameter worms:

up to approx. Ø350 mm

(larger diameters possible in cooperation)

Single flank rolling test according to DIN 3974:

Gear measurement up to centre distance

approx. 1.200 mm

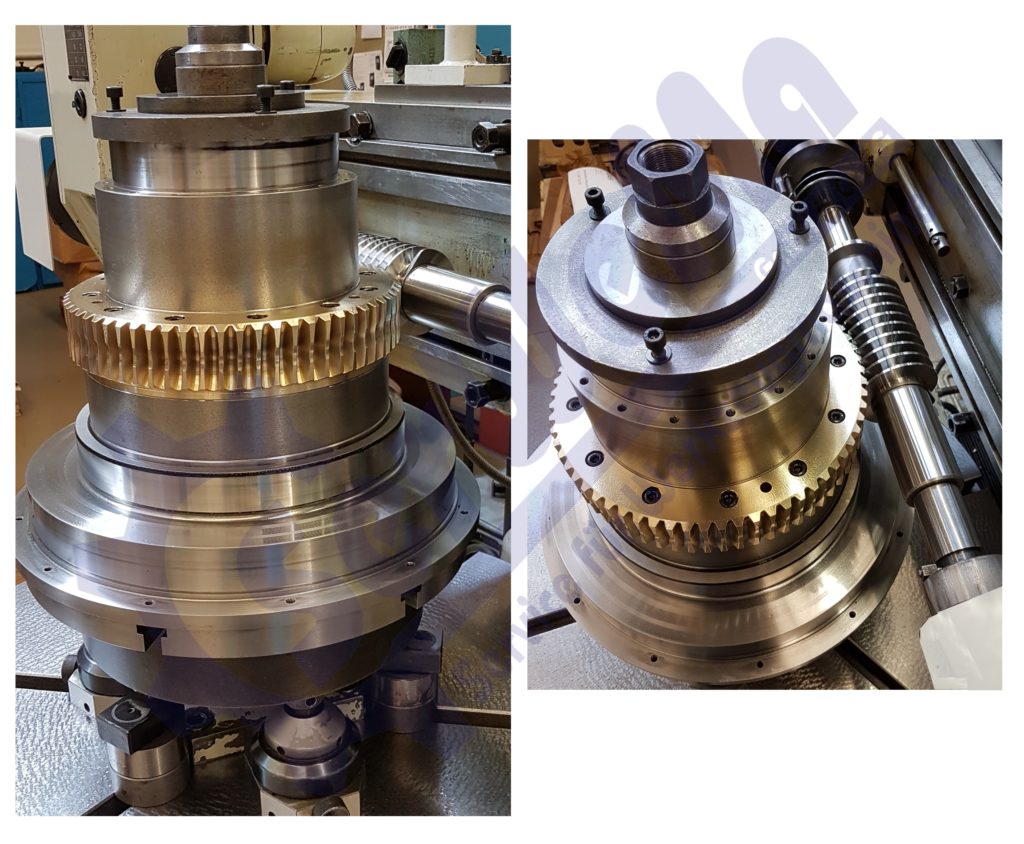

Repair of worm gear units

Defective, damaged or condition unknown?

Machine tables, dividing tables, rotary tables, positioning tables or others; we provide uncomplicated assistance with repairs or machine downtime and can offer fast response times. Repairs are one of our strengths!

Ask us, if necessary we can carry out disassembly, geometric repair, repair of the gear teeth, new storage

and assembly as a complete service.

Gearbox replacement production for e.g..:

- Round Tables

- Machine tables

- Subtables

- Positioning tables

- Swivel units

- Drive units

- elevator and hoisting gear

- Bump heads

Mechanical production parts

Due to our competence in machine overhaul, we are constantly confronted with the task of reconditioning the most diverse

to manufacture turned and milled parts, as well as the most diverse complex parts within reasonable periods of time.

We manufacture among other things:

- Milling arbors

- Milling spindles

- Shaping spindles

- Work spindles

- Worm shafts

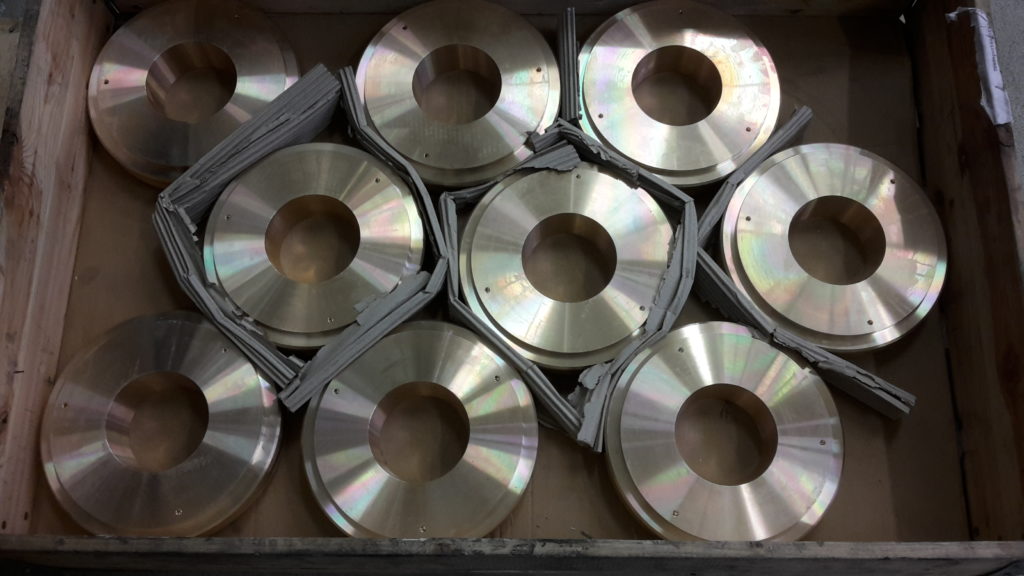

- Flanges

- according to drawing or if necessary according to sample

- Single pieces and small series

We would be pleased to check your requirements!

Repairs

We provide uncomplicated assistance with emergency repairs and machine downtime and act as quickly as possible in such cases.

Turn:

Ø300 mm x 1500 mm

External cylindrical grinding:

Ø 500 x 1500 mm

Thread grinding:

up to Ø315 mm x 650 mm

Trapezoidal thread grinding:

Ø350 mm x 900 mm

Center grinding:

up to Ø120 mm x 950 mm

Surface grinding:

1500 mm x 600 mm